Starting with the 'glue' part of stich and glue.

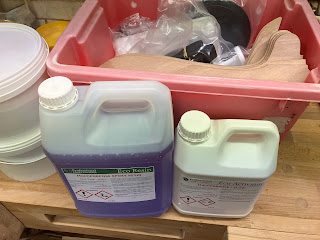

Here is the bow section of the boat coated with its fillets of epoxy, glass tape and then a coat of clear epoxy. The actual gluing stuff went pretty well, but I had a near disaster when mixing up some of the epoxy. The pump on the resin dispenser collapsed through into the container so I was left with a sticky mess and not enough hands to deal with it...I was really glad I was wearing gloves! I managed to fix it, but it isn't holding the seal very well and needs re-priming after each use. The last photo shows the rear bulkhead. This came in the kit with a routed hole for a screw in hatch, but as I am going for deck hatches, I filled it in with epoxy (and drilled a little hole for a drain plug). It will get a coat of paint in due course.